Featured Categories

Buy from the world’s most prestigious luxury brands and trusted agents, brokers, and dealers around the world. Find Luxury Real Estate, Super-yachts, Exotic Cars, Fine Art, Jewellery and Collectables.

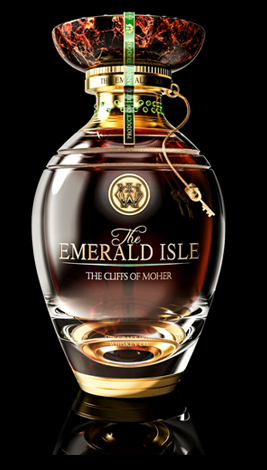

An ultra-rare collection of just seven bottles.

The oldest and rarest whiskey in existence and the world’s first Fabergé Celtic Egg. A handcrafted heirloom collectable of the highest calibre.

The first luxury whiskey set of The Emerald Isle Collection sold at auction for a record-breaking $2,000,000 and the remaining sets were launched at exclusive events across the world throughout 2021, achieving upwards of $3,000,000 - Just one remain.

Buy Luxury with Cryptocurrency

Buyers can purchase any of 221 luxury real estate properties and lifestyle assets with cryptocurrency and sellers can receive the payment in the currency of their choice.

Too Busy or Overseas or Need to build an asset portfolio with maximum return?

221 is the Best Service for Buying and Selling Properties and Houses Abroad. With the expertise of our ever-expanding specialist team of “International Luxury Ambassadors”, 221 will provide you with a first-class service in helping you to buy the perfect luxury home or portfolio in over 15 countries.

221’s Luxury Private Network has over 5,500 agents around the world and can access the ultra private and totally off-market properties to find you the most amazing properties or assist you in building the ultimate investment portfolio.

Our Luxury Ambassadors will find you the properties that nobody else knows about, reach sellers that don’t advertise in the public market. You will gain 100% private access to the best kept secrets around the world.

Our Clients

- HNWI & UHNWI

- Celebrities & Entrepreneurs

- Company Executives

- Real Estate Agents & Brokers

- Luxury Lifestyle brokers

- Art Curators & Art Dealers

- Corporate Investors

- Trust Funds

- Real Estate Investment Trust

- Private Investment Groups

- Family Offices

- Wealth Managers

- Financial Consultants

- Advisory firms

- Private Bankers

Why should you buy with 221

221 curates the most exceptional Real Estate Properties, Super Yachts, Exotic Cars, Fine Art,Antiques and Collectables for discerning buyers and investors from the very best brands, agents, brokers and dealers around the world.

WATCH THE VIDEO

221 Platinum Members

221 Platinum members redefines the world of luxury excellence. These prestigious international brands have a consistent track record of representing some of the most extraordinary real estate properties, yachts and fine arts of all time. Welcome to the best of the best.

Search Prestige Real Estate

Find exceptional Real Estate, including Houses, Chalets, Penthouses, Mansions, Apartments, Condos for Sale

Not sure where to search… select a country or city below to browse through some of the most popular searches

Barbados

Belgium

Canada

Chile

France

Italy

- All Italy

- Arezzo

- Bari

- Bologna

- Brindisi

- Castiglioncello

- Catania

- Cetona

- Como

- Cortona

- Florence

- Forte dei Marmi

- Grosseto

- Lazio

- Lecce

- Liguria

- Lombardy

- Lucca

- Milan

- Monte Argentario

- Monte San Savino

- Montepulciano

- Naples

- Piedmont

- Pienza

- Portofino

- Positano

- Porto Ercole

- Porto Santo Stefano

- Puglia

- Riccione

- Rome

- Sardinia

- Tuscany

- Umbria

- veneto

- Venice

- Verona

Malta

Mexico

Monaco

Morocco

Spain

- All Spain

- Altea

- Barcelona

- Balearic Islands

- Benahavís

- Bendinat

- Benissa

- Canary Islands

- Calp

- Catalonia

- Ciutadella

- Costa del Sol

- Costa Blanca

- Costa Brava

- Costa del Maresme

- Formentera

- Ibiza

- Javea

- Las Rozas De Madrid

- Madrid

- Malaga

- Mallorca

- Maó

- Marbella

- Menorca

- Moraira

- Orihuela

- Palmanova

- Sant Antoni De Portmany

- Santa Eulària Des Riu

- Seville

- Valencia